An introduction to TDLAS and its use for moisture measurement in gas

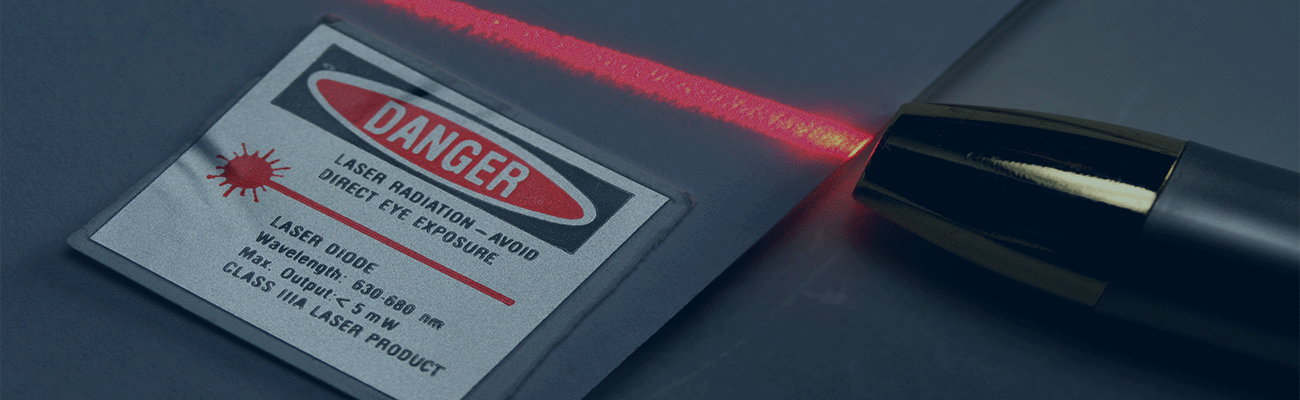

There are various methods of measuring water vapor in process gases. Most have been available for some time and include chilled mirror, ceramic metal-oxide sensors and quartz crystal. More recently, however, a new technology has emerged, based on the use of laser light to detect the concentration of water vapor in a gas stream. This is called Tunable Diode Laser Absorption Spectroscopy, or TDLAS for short.

But what is TDLAS and how does it work?

What is TDLAS?

In simple terms, a TDLAS analyzer works by shining a beam of infra-red light through a sample of gas held in a measuring cell. The laser and a detector are located at one end of the cell. There is a reflective surface at the other end, allowing light to be bounced back from the laser to the detector. Water molecules in the gas will absorb a percentage of the light energy at certain wavelengths. The amount of energy loss is measured at the detector, where it is represented as a loss of color across the spectrum, otherwise known as absorption lines. The intensity of these lines will be proportional to the concentration of vapor.

The first TDLAS analyzers date back to the early 1970s, with instruments that were originally produced for specialized academic laboratory and research applications, such as atmospheric monitoring. Development of the technology was initially limited by the nature of the laser sources that were available. These were lead-salt laser diodes with detectors constructed from lead selenium or mercury cadmium telluride, which needed to be cooled to cryogenic temperatures to function reliably.

In the following decades, the rapid growth in the telecommunications industries led to the development of increasingly sophisticated laser technologies, while the entry of new manufacturers into the market helped to create commercially available products at realistic cost. Today, it has become common practice to use the latest tunable near-infra-red diode lasers for spectroscopic gas detection.

As the name implies, these instruments can easily be tuned to precisely targeted wavelengths, enabling specific molecules to be detected in a gas sample; in practice, this means that just a single absorption line can be resolved. They also provide a coherent light, enabling them to be used with samples that have high particulate loadings, while offering excellent sensitivity down to ppm levels, with an accuracy to within 1 % of the reading. They operate at room temperature and are normally stable and reliable, meaning they have a long operating life. This makes them ideal in, for example, critical applications such as natural gas processing and transportation.

The OptiPEAK TDL600 from Michell Instruments

At Michell Instruments, we’ve been manufacturing advanced TDLAS analyzers for many years. Our latest model is the OptiPEAK TDL600, which has been developed primarily for the measurement of moisture in variable compositions of natural gas and bio-methane.

The OptiPEAK TDL600 combines the most recent advances in tunable diode laser technology with powerful signal processing capabilities. This has resulted in an instrument that is rugged, reliable and extremely accurate, even in the most demanding applications, such as fluctuating methane concentrations or measurement in sour gas.

In brief, the OptiPEAK TDL600 offers:

Learn more about the OptiPEAK TDL600

With over 40 years’ experience in the development of innovative precision instruments, we are the application experts in humidity measurements for natural gas processing and pipeline transmission applications. If you would like to discuss your requirements, please contact our team today.

Look out for our next blog about TDLAS, where we will delve a little deeper into how the technology works and look at how it can be used to detect water vapor in process gases.

The fundamental foundations for laser technology were established by Albert Einstein in 1917 in his paper ‘On the Quantum Theory of Radiation’, but it was not until 1959 that the term LASER (standing for Light Amplification by Stimulated Emission of Radiation) began to be widely used. Laser technology emerged from earlier experiments using microwave amplification, or MASER (Microwave Amplification by Stimulated Emission of Radiation).

The issue of who can lay claim to being the first to patent a laser device is unclear, following a 28-year legal dispute between scientist Gordon Gould and Bell Laboratories. What is certain, however, is that the first laser device was operated at the Hughes Research Laboratories in California in 1960, where scientist Theodore Maiman demonstrated the excitation of a ruby with a pulsed light source. At the time, this created considerable media interest, including sensationalist reports of a new ‘death ray’. Thankfully, since then, laser technology has been harnessed for much more peaceful and wide-ranging industrial and scientific purposes!

Related Information

Use TDLAS Moisture Analyzers to Monitor Moisture in Stored Natural Gas

Related Blogs

Precise Measurement of Moisture in Natural Gas

How Novel Optical Moisture Detection can Reduce Risk and Save Costs in Natural Gas Storage

How to Make the Best Choice of Moisture Sensor for your Natural Gas Process

Some Engineers Still Believe these Three False Assumptions about Metal Oxide Moisture

Related Categories

Trace Moisture Analyzers for Natural Gas Quality and Petrochemical Applications

Related Products

Moisture in Natural Gas Analyzer - Michell OptiPEAK TDL600

Process Moisture Analyzer - Michell QMA601

Process Moisture Analyzer - Michell Promet EExd

Want to see more information like this?

Sign up to one of our Industry newsletters and you’ll receive our most-recent related news and insights all directly to your inbox!

Sign Up