The key things you need to know about monitoring glove box inert gases

For decades, isolation and containment glove boxes have served as a crucial tool for primary research in laboratory settings, as well as for testing product quality and facilitating specialized manufacturing processes. These innovative devices are used in a variety of industries and have played a key role in advancing scientific and technological advancements.

Glove boxes first came into widespread use during the Second World War, as research into the development of nuclear weapons and the handling of radioactive materials intensified. Subsequently, glove boxes have played a vital role in the development of new pharmaceuticals and vaccines, they have been used by NASA in their analysis of dust and rocks returned from outer space, and have today become a standard item in universities, laboratories and factories around the world.

What is a glove box?

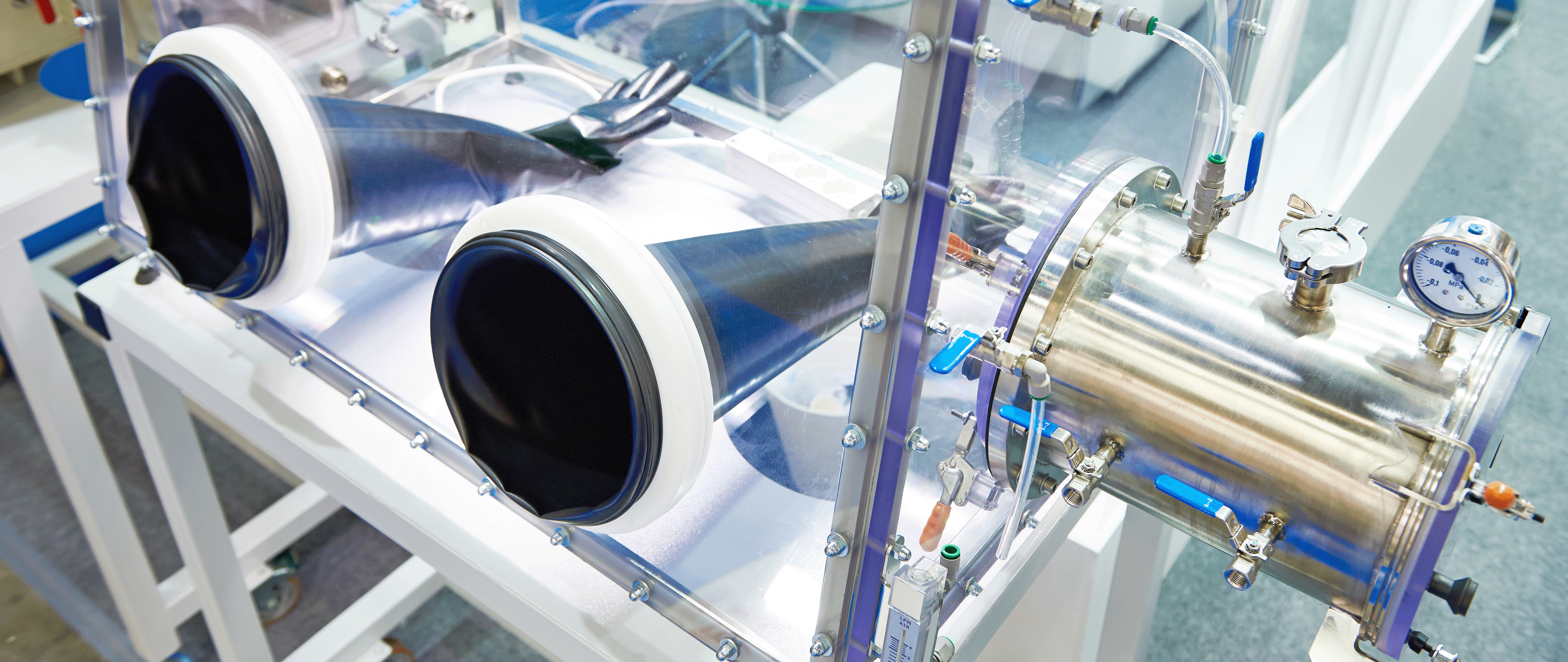

A glove box is essentially a sealed enclosure which is accessed with the use of gloves, allowing the operator to work safely with hazardous or reactive materials. Typically, glove boxes are operated with either a positive or negative pressure, depending on the intended purpose. Positive pressure is used when the process needs protection from the external environment, which involves purging the enclosure using an inert or blanketing gas. Negative pressure is used when the operator needs to be protected from contamination.

Nitrogen, argon and helium are the most commonly used inert gases. Regardless of inert gas, water vapor presence must be monitored both to maintain atmosphere integrity within the glove box and to detect any leaks as early as possible. Depending on the nature of the application, the presence of moisture can cause a reduction in yields, unwanted reactions, an adverse effect on the surface or structural integrity of materials such as thin-film wafers or, where nucleotides are being processed for use in calibration instruments, an attenuation of radioactive emissions.

Most glove boxes are designed to be used as stand-alone units. However, the digitization of industrial products, such as our Easidew M12 digital transmitter, plus the growth of Industry 4.0 (I4.0) methodologies and the need to improve traceability and quality procedures, are leading to an increase in demand for dew-point sensors that can be connected to higher-level monitoring systems.

Why dew-point sensors are crucial in measuring moisture in inert gases

Moisture presence in the inert gas is likely to indicate either a leak to atmosphere or a problem elsewhere with the gas supply and pressurization system. For some applications, even a small level of moisture contamination – down to a few ppm – may be sufficient to compromise the integrity of the research or production process.

Precise and continuous moisture measurement, using an advanced dew-point sensor, is therefore critical. Perhaps just as importantly, this sensor must be located correctly within the glove box to ensure that readings are accurate.

One of the challenges is the low level of gas flow within a glove box. It is, therefore, best practice to locate the dew-point sensor close to the glove box exhaust, as this is where the flow rate is highest and capable of producing sufficient gas flow across the face of the sensor mechanism to generate consistent readings. It should be noted that fluctuations in the flow rate must be considered, to minimize the risk of inconsistencies.

What should OEMs consider when choosing a dew-point sensor?

Aside from the need to install dew-point sensors or transmitters in the best location to ensure accurate and consistent results, there are a number of other factors that glove box OEMs should take into consideration.

Specify sensors correctly to meet positive pressure and vacuum glove box needs, and conform to process conditions, especially when handling aggressive materials or gases. Ideally, sensors should have KF40 and KF25 process flanges for quick, leak-free installation. Avoid dead zones with zero gas flow in glove box design to prevent moisture trapping. Needless to say, if such a zone cannot be eliminated, the moisture sensor should not be located in this area, otherwise it will give incorrect readings.

Our Easidew EA2 dew-point transmitters offer analog and digital connectivity, are certified for use in hazardous areas, and are designed to be easily integrated into centralized monitoring and control platforms. They allow critical data to be captured in real time, to help improve the quality, performance and reliability of research and manufacturing operations.

To find out more, read our post about critical measurements in inert glove boxes.

View our full range of dew-point transmitters and sensors

With almost 50 years’ experience in the development of innovative precision sensors, we are the application experts in dew-point and moisture measurements for all glove box applications. If you would like to discuss your requirements, please contact our team today.

Related Products

Dew-Point Transmitter - Michell Easidew EA2

Compact SIL2 Capable Oxygen Analyzer - Ntron SIL-O2

Want to see more information like this?

Sign up to one of our Industry newsletters and you’ll receive our most-recent related news and insights all directly to your inbox!

Sign Up