Air conditioning and climate control systems are used in a wide range of environmental conditions across the world. The primary purpose of these systems is to maintain thermal comfort by regulating indoor air temperature and humidity.

To maintain air quality, fresh outside air is continuously drawn into the HVAC system and conditioned before being circulated indoors. However, due to varying local climates, outside temperatures could be anywhere between -50 … +50 °C, with humidity levels between -30 … +30 °C dew point.

Designing a system with satisfactory performance across such a wide range of conditions is a challenge, therefore HVAC systems need to be properly set up, and subject to a rigorous testing regime before sale. The purpose of this testing is not only to evaluate the performance of the systems temperature and humidity control, but to ensure the system is energy efficient, filled with the correct level of refrigerants and is not subject to any leaks or problems with drainage.

The use of air conditioning systems has increased around the world in recent years, partly driven by climate change. Since operating an air conditioning system consumes energy, making sure the system operates efficiently as possible is more important than ever.

A typical HVAC test procedure

To ensure product quality, each system is tested in a variety of environmental conditions to ensure that the following parameters are within acceptable limits at the outlet:

The purpose of the tests is to validate the performance and efficiency of the system, and to determine the required fill level of refrigerant gas.

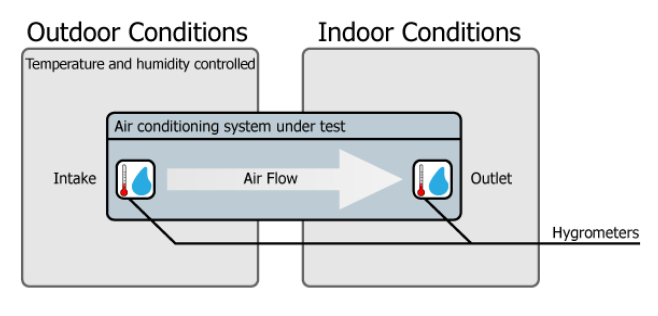

Each manufacturer will operate multiple test rigs. These consist of a pair of environmentally controlled chambers: one to simulate conditions outdoors, and another to simulate conditions indoors. The system under test is connected between these two chambers and run in a variety of different ‘outdoor’ climatic conditions, across a set range of temperatures and humidity levels.

Caption: Air conditioning systems are tested for both indoor and outdoor conditions using two climatic chambers and reference hygrometers

Traditionally, psychrometers were installed on both the inlet and outlet of the system under test. A sequence of temperature and humidity test conditions is generated in the ‘outdoor’ chamber.

The readings of the psychrometers on the inlet and outlet are compared at each point: the difference being the effort of the ac unit. These data collected across all points of the test can then be used to determine the cooling and dehumidification efficiency of the device under test, which indicates the refrigerant pressure required for proper operation.

Why are humidity measurements important for testing HVAC systems?

Accurate dew point measurements at the inlet and outlet of the unit under test are crucial. The closer to the true value the measurement is, the more precisely the refrigerant fill level of the condenser can be calculated.

The best way to ensure reliable dew-point measurements is to install a chilled mirror hygrometer into the inlet and outlet ducts. They provide a number of benefits over traditional psychrometers:

However, changes in the temperature of the ‘outdoor’ chamber can happen very quickly, and can cause condensation issues for some chilled mirror sensors. For this reason, a chilled mirror hygrometer that is designed for a fast response is essential to quickly track humidity changes and provide consistent performance.

Recommended PST products

Michell Optidew 501 Industrial Grade Chilled Mirror Hygrometer

A cost-effective chilled mirror hygrometer designed for industrial humidity control. It offers HVAC testers the following:

Highlights

Related Products

Industrial Grade Chilled Mirror Hygrometer - Michell Optidew

Want to see more information like this?

Sign up to one of our Industry newsletters and you’ll receive our most-recent related news and insights all directly to your inbox!

Sign Up