The Importance of moisture measurement to meeting gas-quality and operating-efficiency demands

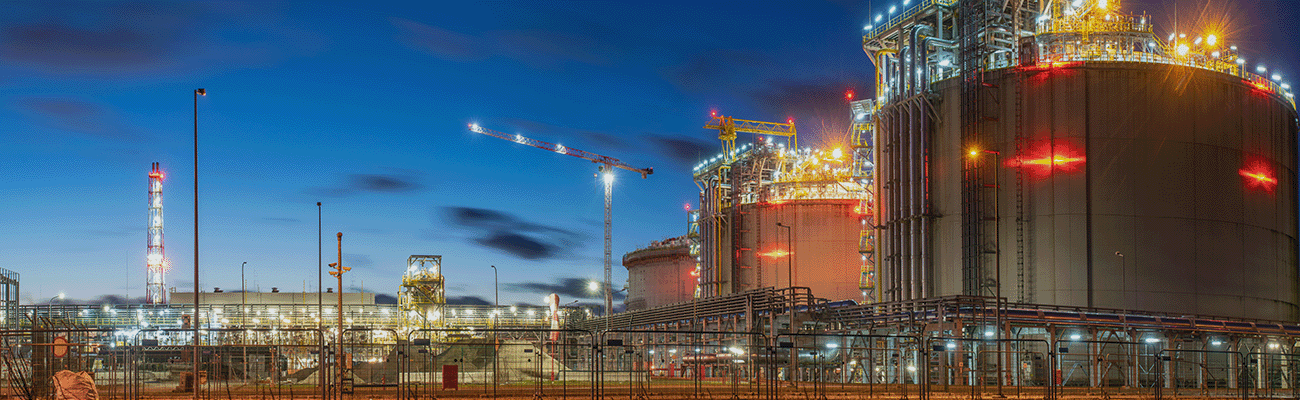

It’s a golden age for liquified natural gas (LNG) – at least, according to a recent expert commentary from the Gas Exporting Countries Forum (GECF), which states the period between now and 2030 will see a steep growth in ‘infrastructure deployment and investment’.

The GECF is an intergovernmental organization with members from many of the major gas producing countries. Their view is that, historically, there has been significant underinvestment in the natural gas supply chain and this has contributed to the ongoing global energy crisis. However, the GECF believes that this crisis is now driving fundamental change in the energy market, including a rapid growth in demand for LNG and LPG (liquified propane gas) products. By 2050, overall demand is expected to rise by 36 %.

The need for urgent and major investment in midstream and natural gas infrastructure is a key message from the GECF, especially for ‘LNG liquefaction, LNG regasification and export pipelines’. The organization anticipates that 2030 will be a ‘boundary year’, after which there will be increasing uncertainty over gas demand and trade as countries pursue different paths towards decarbonization and net zero.

The time required for new LNG facilities to come on-stream means that, for many midstream companies, the pressure is on if they are to capitalize on this growing market opportunity. The good news is that many are ahead of the game.

For example, in the United States there are already eight major LNG export terminals operating around the eastern seaboard and the Gulf of Mexico. A further 16 terminals are either under construction or approved and ready for construction, with at least nine more at the planning stage. Companies are also investing significant sums in other midstream infrastructure, with examples including Enterprise Products Partners’ $3.1 billion NGL pipeline and fractionation complex in Delaware and Texas, and Saudi Aramco’s £3.2 billion expansion of fractionation trains, pipelines, storage and export facilities in Saudi Arabia.

Operational resilience and efficiency are the priority for future LNG systems

Collectively, midstream operators around the world are currently investing (or plan to invest in the near future) many billions of dollars in new LNG infrastructure. In this rush to invest and ensure a relatively fast deployment (in industry terms) of new production facilities, owners and operators should not lose sight of the need for long-term operational resilience and efficiency. After all, the payback periods for many of these investments will be measured in years, making it essential that considerations are made at the outset to ensure that the reliability and operating life of equipment is optimized, with minimal maintenance and servicing costs.

The importance of trace moisture measurement

If we consider, as an example, operating systems such as molecular sieve dehydration columns, turbo-expanders or fractionation towers, all of which are vital to effective process function, then there are several process indicators that must be measured accurately, consistently and, in most instances, in real time. This is crucial for safety, to reduce energy costs, prevent the risk of unexpected failure and downtime, and maximize maintenance intervals and operating life.

Trace moisture measurement is perhaps one of the most important of these indicators. Water in both liquid and gaseous forms is normally present in natural gas at the point of extraction and can subsequently be carried through the process train. It can also occur downstream due to condensation, leaks or changes in process conditions. In each case, its presence can cause corrosion to pipework, the formation of ice with the potential of damaging fast-rotating blades in turbo-expanders, or a degradation in the quality of the final gas product.

Precise measurement of water vapor within molecular sieve dehydration columns is also vital if the total adsorption capacity of each dryer column is to be optimized. Instruments such as our QMA601-LR process moisture analyzer provide almost real-time measurement of ultra-low trace moisture content down to 0.02 ppmv. This allows engineers to test and then operate dryers safely to their desiccant break-through point, enabling regeneration cycles to be reduced, energy costs to be cut and the life of desiccant materials to be extended.

Payback, margins and profitability

Although high-quality, high-performance trace moisture measurement instruments may have a relatively high price tag, the improvements in efficiency, safety and productivity that they can deliver mean that payback, or return on investment, can be rapid. This is an important point, especially as we look towards the future where LNG midstream processing has to operate in an ever more competitive global energy market, and where precise control of capital and operating costs will be essential to ensure the best margins and long-term profitability.

With 50 years’ experience in the development of moisture, humidity and dew-point technology, we are the application experts for all LNG applications. If you would like to discuss your requirements, then please contact our team today.

The United States is the world’s largest producer of natural gas, representing almost a quarter of all output. Russia, Iran, China and Canada make up the rest of the top five producers, as of 2023.

When it comes to LNG, the countries with the largest operational capacity, as of 2022, were Australia, Qatar, the United States, Malaysia and Algeria. However, the United States again led the way in 2023 being the largest exporter of LNG, with much of its production heading to Europe.

LNG is shipped between countries by bulk LNG carriers. In 2023, there were over 700 of these large vessels in the global LNG fleet. There are currently more than 370 being built, or on the order books of shipyards around the world. The biggest of these ships measure over 350 m in length and are around 50 m wide, with a draught of 12 m and a capacity in excess of 260,000 m3 of liquid gas.

Related Information

Products and Services for the Natural Gas Sectors

Related Blogs

Best Practices for Measuring Dew Point in Transmission Gas

Moisture Measurement and Liquified Natural Gas

Related Categories

Related Products

Process Moisture Analyzer - Michell Promet EExd

Process Moisture Analyzer - Michell Promet I.S

Low-Range Process Moisture Analyzer - Michell QMA601-LR

Want to see more information like this?

Sign up to one of our Industry newsletters and you’ll receive our most-recent related news and insights all directly to your inbox!

Sign Up