The SenzTx Oxygen Transmitter from Process Sensing Technologies (PST) utilizes proven sensor technology to provide accurate oxygen concentration measurement. The compact design enables easy integration, with an option of process connections for inline and extractive measurement applications.

The SenzTx is suitable for use within numerous applications including oxygen and nitrogen gas generation, glove box purge and leak detection, industrial gas applications, and measurement solutions for medical gases.

With a choice of zirconia or electrochemical sensor technology, the SenzTx offers reliability, accuracy, and flexibility with a broad measurement capability with transmitters covering the ranges of measurement from 0...10ppm up to 100% oxygen.

Engineers are constantly looking for new and innovative ways to improve the efficiency of their work. In many cases, this involves finding the correct product. When it comes to oxygen transmitters, the SenzTx Oxygen Transmitter is a great option to consider. Here are three key factors to keep in mind when making your decision:

1. Measurement Technology

2. Measurement Range

3. Process Connection

1. Measurement Technologies

When choosing the measurement technology for your SenzTx, it is important to consider the type of gases that will be present in the monitored environment. Inert gases, such as nitrogen and argon, can be detected using either electrochemical (EC) or Zirconia (ZR) sensing technology. However, hydrogen and helium, as well as other gases with combustible properties, must be detected using Electrochemical sensing technology.

Enriched oxygen levels (<25%) MUST be monitored with our zirconia sensing technology. Standby nitrogen generators or gloveboxes where the sensor could be exposed to air for long periods would also benefit from the zirconia sensor choice.

By considering the composition of the gas mixture, you can select the SenzTx that is best suited for your needs.

Electrochemical:

How does it work?This sensor has a membrane, cathode, anode, electrolyte and measurement circuit. As oxygen diffuses through the membrane into the electrolyte it causes a reaction between the cathode and anode causing an electro-magnetic force. This current caused by an electro-magnetic force is proportional to the amount of oxygen present in the sample gas.

The sensing technology measures the pressure of oxygen within the sample gas which means it can be affected by variations in pressure. The sensor needs to operate between +/- 100mbar from atmospheric pressure.

The electrochemical sensing technology enables the sensor to measure oxygen in gases with hydrocarbons and silicone vapors present in the gas.

How long does it last?

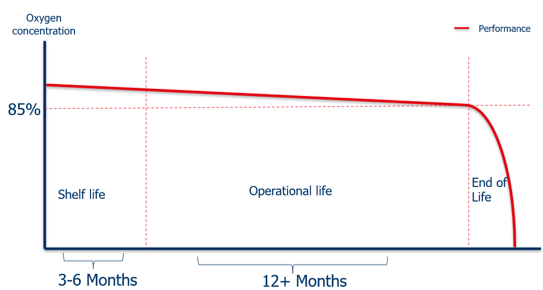

Depending on the application the EC sensor can last anywhere from 12-24 months. Sensor life is a combination of shelf life and the operational life. Shelf life is typically 3-6 months when stored in an inert environment. Operational life in excess of 12 months, application dependent.

Factors that affect the Sensor life

Zirconia:

How does it work?

This sensor has a long service life with virtually no drift. A small capillary on the sensor controls the diffusion of oxygen into the sensor. When heated to over 400°C oxygen is electronically reduced causing current flow through the zirconia electrolyte. Zirconium oxide allows the movement of oxygen ions through the substrate from a high to a low concentration. The measurement of oxygen is determined by the current flowing through the electrodes.

How long does it last?

Depending on the application the zirconia sensor can last five years plus. (clean dry gas application)

Factors that affect the Sensor life

2. Measurement Range

Electrochemical:

There are 2 sensor ranges for the electrochemical SenzTx which can be configured as follows; 0 - 1000PPM (0 -10,100,1,000), 0-25% (0 -1,25)

Zirconia:

There is the option for a zirconia sensor on all ranges for the SenzTx;

0 - 1000PPM (0-10,100,1,000), 0-25% (0 -1,25) 0-100% (0-96,100)

On the high percentage sensor, the range is limited to 99.4%. When tested the sensor was able to measure up to 99.4% accurately before it tailed off. We say 100% as we state that our measurements are accurate within +/-2% of the reading.

| 0-100ppm | 0-1000ppm | 0-1% | 0-25% | 0-96% | 0-100% |

| ZR or EC | ZR or EC | ZR or EC | ZR or EC | ZR | ZR |

3. Process Connection

There are three different process connections available with the SenzTx

KF-40 Flange

Flow through base

Flow through base with an orifice

These enable direct insertion and remote mounting of the transmitter for an extractive measurement.

KF-40 Flange

The KF-40 connection enables a direct insertion inline connection. It is an ISO-standardized vacuum fitting that provides a vacuum seal by compressing a rubber O-ring between two mating surfaces.

The KF-40 flange is ideal for quickly assembling vacuum systems thanks to their ease of use, maintenance, and reusability.

Flow through

The flow through base is used in an extractive measurement solution where a sample gas is passed over the sensor. This must be used with a metering valve and a pressure regulator.

Flow through with orifice

The orifice on the inlet of the flow through ensures a stable flow rate over the sensor from a fixed pressure input (typically 2Barg, 30Psig).

For a customer, choosing the flow through with the orifice gives them an easier, lower cost installation when compared to a regular flow through base.

. The sample gas pressure is the same for both zirconia and electrochemical measurement technologies.

For both electrochemical and zirconia technology variants, the flow rates are 250ml – 1L/min.

Application Specifics

The SenzTx is suitable for use within clean gas applications. These include oxygen and nitrogen gas generation, glove box purge and leak detection, industrial gas applications, and measurement solutions for medical gases.

With a choice of zirconia or electrochemical sensor technology, the SenzTx offers reliability, accuracy, and flexibility with a broad measurement capability with transmitters covering the ranges of measurement from 0...10ppm up to 100% oxygen.

Certification

The SenzTx Oxygen Transmitter is designed for safe area use only and is currently available with Marine certification. For hazardous area and SIL-capable oxygen products, we recommend looking at PST’s current offering here.

Related Products

Compact Oxygen Transmitter - SenzTx

Want to see more information like this?

Sign up to one of our Industry newsletters and you’ll receive our most-recent related news and insights all directly to your inbox!

Sign Up